#1 Precision CNC Plastic Injection Mold Manufacturer in Ho Chi Minh City

In the field of modern industrial manufacturing, CNC plastic injection mold machining plays a leading role. A high-quality mold not only helps businesses improve productivity but also directly determines the quality of the final product. With over 15 years of experience, Bao An Company is proud to be one of the most trusted plastic injection mold manufacturers in Ho Chi Minh City, providing plastic injection mold machining, plastic product manufacturing, and plastic brick molding services with premium quality.

In this article, Bao An will walk you through plastic injection molds, the plastic injection mold manufacturing process, and the reasons why many customers trust Bao An as a reliable plastic injection mold company in Ho Chi Minh City.

What is a plastic injection mold?

A plastic injection mold is a critical component in the plastics industry, designed to shape products according to specifications. When molten plastic is injected into the mold, it gradually cools and forms a product that matches the design with high precision.

Plastic injection molds are usually made of high-quality steel, processed with advanced technologies such as 5-axis CNC, EDM cutting, turning, and precision milling. Depending on requirements, molds can be designed with single or multiple cavities, helping to optimize production efficiency.

With more than 15 years of experience, Bao An has manufactured thousands of plastic injection molds for industries such as construction, furniture, electronics, and healthcare. Among them, plastic brick molding is one of our strongest specialties, trusted by many businesses.

Plastic injection molds are widely applied in multiple industries:

- Electronics & Appliances: computer cases, TVs, fans, sockets, and electronic components.

- Automotive & Motorcycles: plastic parts for car interiors, motorcycle components.

- Construction: plastic bricks, wall panels, decorative accessories.

- Consumer goods: household plastic, bottles, trays, medical plastic products.

Key factors that determine mold quality

A high-quality plastic injection mold must ensure:

- High precision: product dimensions must perfectly match the design with minimal error.

- Durability and long lifespan: withstand hundreds of thousands to millions of molding cycles without damage.

- Easy mold release: optimize production time.

- Surface quality: glossy finish, minimal flash, and defects.

👉 In short, the plastic injection mold is the “soul” of the production process. Investing in high-quality molds means increasing competitiveness for your business.

Plastic injection mold manufacturing process

To create high-quality molds, Bao An plastic injection mold manufacturer always follows strict processes, combining modern technology with the expertise of skilled engineers.

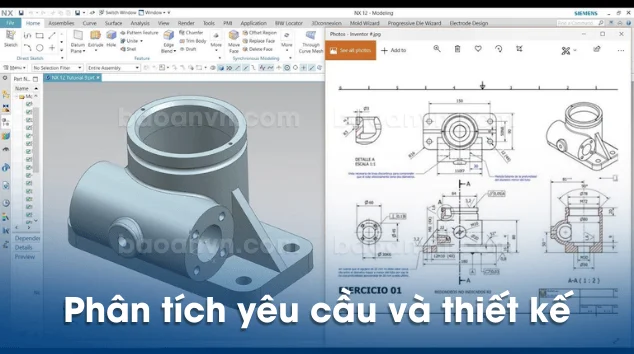

1. Requirement analysis and mold design

- Receive drawings or product samples from customers.

- Analyze shape, structure, materials, and suitable molding methods.

- Create mold drawings using CAD, SolidWorks, UG, ProE, and other design software.

- Simulate molding process (CAE) to predict deformation, shrinkage, and plastic flow.

2. Choosing mold materials

At Bao An plastic injection mold company, we typically use steels such as P20, H13… These are heavy-duty mold steels.

What is P20 steel?

P20 steel is an alloy tool steel commonly used in plastic injection mold machining. It is pre-hardened, providing stable hardness, easy machining, and is suitable for medium to large molds.

P20 is cost-effective and widely used for general-purpose plastic molds.

What is H13 steel?

H13 steel is a Hot Work Tool Steel under AISI standards (USA), containing high Cr – Mo – V content. It offers excellent heat resistance, wear resistance, and thermal crack resistance, commonly used for molds and tools operating at high temperatures.

H13 can withstand continuous working temperatures up to ~600°C, resisting thermal shock while maintaining hardness.

3. Mold machining

- 3–5 axis CNC: milling, drilling, turning with ±0.005 mm precision.

- EDM machines: processing small cavities and complex details.

- Surface & cylindrical grinding: ensuring smooth finishes.

- Heat treatment: increasing mold hardness and durability.

4. Mold assembly and inspection

- Engineers assemble mold components.

- Check alignment, clearance, cooling system, ejectors, and sliders.

5. Trial molding and adjustment

- Conduct trial runs (T0, T1, T2).

- Inspect samples: dimensions, finish, durability.

- Adjust molds until final product meets standards.

6. Finishing and handover

- Polish mold, anti-rust treatment, and quality inspection.

- Deliver with maintenance guidelines.

👉 Thanks to strict and closed processes, Bao An molds always achieve high precision and long service life, helping businesses produce with peace of mind.

Plastic injection mold manufacturer in Ho Chi Minh City

There are many providers on the market. However, if you are looking for a plastic injection mold CNC company in Ho Chi Minh City that is both reliable and experienced, Bao An is your trusted partner.

Advantages of Bao An Company

- 15+ years of experience: serving hundreds of domestic and international clients.

- Modern equipment: 5-axis CNC, EDM, lathe, milling, and grinding machines.

- Skilled engineers: mastering processes, always creative in design.

- Cost-effective solutions: balancing mold quality and business budget.

- Full-package service: design, machining, manufacturing, and maintenance.

Main services at Bao An

- Plastic injection mold machining: household, industrial, electronic, automotive plastic parts.

- Plastic brick molding: for the construction industry.

- Plastic product manufacturing: mass production based on requirements.

- Mold maintenance & repair: extending lifespan, reducing investment costs.

Applications of Bao An plastic injection molds

- Electronics: computer cases, electronic components.

- Automotive & Motorcycles: plastic accessories, interior parts.

- Household: plastic boxes, bottles, trays.

- Construction: plastic bricks, decorative accessories.

Contact Bao An – Your trusted partner in plastic injection mold manufacturing

If you are looking for a plastic injection mold manufacturer in Ho Chi Minh City, contact Bao An Company today for detailed consultation.

- Hotline: 0909.677.296

- Email: marketing.global@baoanvn.com

- Website: www.baoanvn.com

- Fanpage: Bao An Global

👉 With the motto “Precision – Durability – Optimization”, Bao An is committed to delivering high-quality mold solutions that help businesses improve productivity and achieve sustainable growth.